|

Firefighting existed before the hydrant and the idea of getting the wet stuff onto the red stuff is very old. The inventor of the first device that we'd recognize today as a fire hydrant can't be told, because the hydrant was developed over a period of many years by many people. The first hydrants were used for public water supply from the earliest municipal water systems. They resembled faucets and were at best suited for the bucket brigade method of firefighting. Prior to municipal water systems, there were other means to provide water in the event of a fire.

Photo ©2001 Wan-i Yang Firefighting cauldrons were placed in strategic locations in ancient China and kept filled with water --- at the ready --- in the event of a fire. In colonial America cisterns were used to store water for early fire fighting purposes, and these continued to be used even after the introduction of the hydrant in many cities. Moreover, as late as 1861, Louisville, Kentucky employed 124 cisterns but no fire hydrants. Cisterns are still used today for firefighting. |

In the beginning, the original "hydrant" may have been something like this iron cauldron from China

In the beginning, the original "hydrant" may have been something like this iron cauldron from China

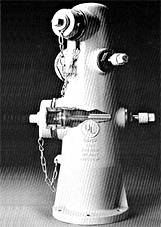

Early Fire Hydrants Often Had Wooden Cases

Early Fire Hydrants Often Had Wooden Cases